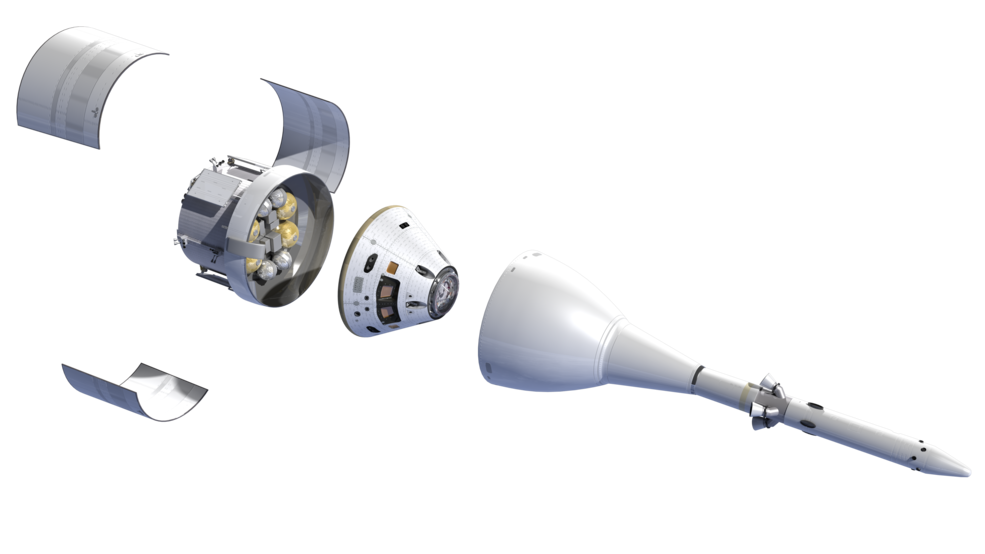

Lockheed Martin is using AR to build NASA’s Orion spacecraft on their mission to Mars.

Lockheed Martin Corp’s engineers thoroughly understand the of power of AR technology and its potential as a revolutionary tool in the work environment as a digital infrastructure. So much so that the American based global technologies company is turning to augmented reality to develop a faster and more efficient process to manufacture NASA’s Orion spacecraft which will be used for the first deep-space mission to send humans to Mars.

Using a technology like AR to mix 3D digital images with objects in the real world would not only give engineers a more efficient way of visualizing the development of spacecraft technology, but also allow them the ability to explore possible design flaws from multiple view points, and resolve them at an increased rate of speed.

This would be a huge benefit for the team behind NASA’s Orion spacecraft project.

Yes, it sounds a lot like something you would see in one of Marvel’s Iron Man movies – only it’s not a special effect, it’s very real, and could potentially benefit human kind on a large scale.

Yvonne Hodge, VP and CIO for Lockheed Martin’s space division said in a WSJ interview, “This is a really exciting capability that can really accelerate us and make us more competitive,” adding, “when you look at return on investment, you’re really talking about reducing cycle time and defect rate, and that’s pretty exciting.”

Since the introduction of Google Glass and Microsoft’s HoloLens, multiple manufacturing companies such as Lockheed Martin, AGCO Corp and Boeing have all turned to AR smart glasses as part of their product design process.

That is a $6 million dollar jump and almost 400,000 more U.S. based employees in AR headsets according to data collected in 2016.

Lockheed Martin recently tweeted their commitment towards using AR technology for the NASA Orion project, stating “From paper instructions to 3-D computers…we’re constantly adding new technologies like augmented reality #AR to speed up spacecraft production, like on @NASA_Orion.”

AR isn’t a new technology for the company. During a 2015 project with NGRAIN, Lockheed Martin turned to AR glasses to build F-35 fighter jets, giving employees a set of Epson Moverio BT-200 glasses to make sure every part of the jet was where it needed to be. Employees were able to visualize each component and see assembly information, vastly improving how fighter jets were constructed.

Lockheed Martin also leveraged software such as Scope AR on past projects. Because Scope AR didn’t require a lot of coding, it made it easier faster for designers to develop 3D objects for each individual project.

Using AR within Lockheed Martin’s work environment even had a financial impact on how the company operated by cutting the cost and time to train new employees. Instead of being in a classroom reading manuals or white pages, employees were actively performing actual tasks with the help of AR.

This meant you could learn on the go, develop muscle memory of an assembly process and have a more interactive learning experience.

Overall, AR glasses made a huge improvement on how Lockheed Martin employees worked. The technology almost doubled the retention rate of new knowledge which meant employees worked almost 30 percent faster, with up to 96 percent accuracy.

However, the technology isn’t perfect and Lockheed Martin isn’t committed to fully outfitting every single employee with an AR headset – but they do see the potential of immersive technology.

NASA’s Orion will launch into deep-space in early 2020 from Kennedy Space Center in Florida with the plan of bringing a human crew to Mars. The Lockheed Martin manufactured vehicle is able to provide emergency abort capabilities, sustain astronauts during their mission, and provide safe re-entry from deep space return velocities.

Image Credit: Lokheed Martin / NASA

The post Lockheed Martin Is Manufacturing Spacecrafts With The Help Of AR appeared first on VRScout.

from VRScout https://ift.tt/2LSO9V6

via IFTTT

No comments:

Post a Comment